You bought a red dot for your pistol. Now you're staring at mounting options that make zero sense. Direct mount, adapter plates, dovetail cuts, MOS systems, CORE slides — and somehow none of the manufacturer websites actually tell you what works with what.

Here's the thing: pistol red dot mounting isn't complicated once you understand the footprint system. Every optic has a mounting pattern (footprint), every pistol has a cut or mounting system, and you need to match them up. The problem is manufacturers love proprietary systems and marketing names that obscure the actual compatibility.

I've mounted dozens of red dots on everything from Glocks to 1911s, and the mounting headaches always come down to the same issues: wrong footprint, bad adapter plates, or trying to force compatibility that doesn't exist. Let me save you the trial and error.

Understanding red dot footprints

The footprint is the bolt pattern and dimensions where your optic meets the slide. Think of it like wheel bolt patterns on cars — a 5x114.3 wheel won't fit a 5x120 hub, no matter how close they look.

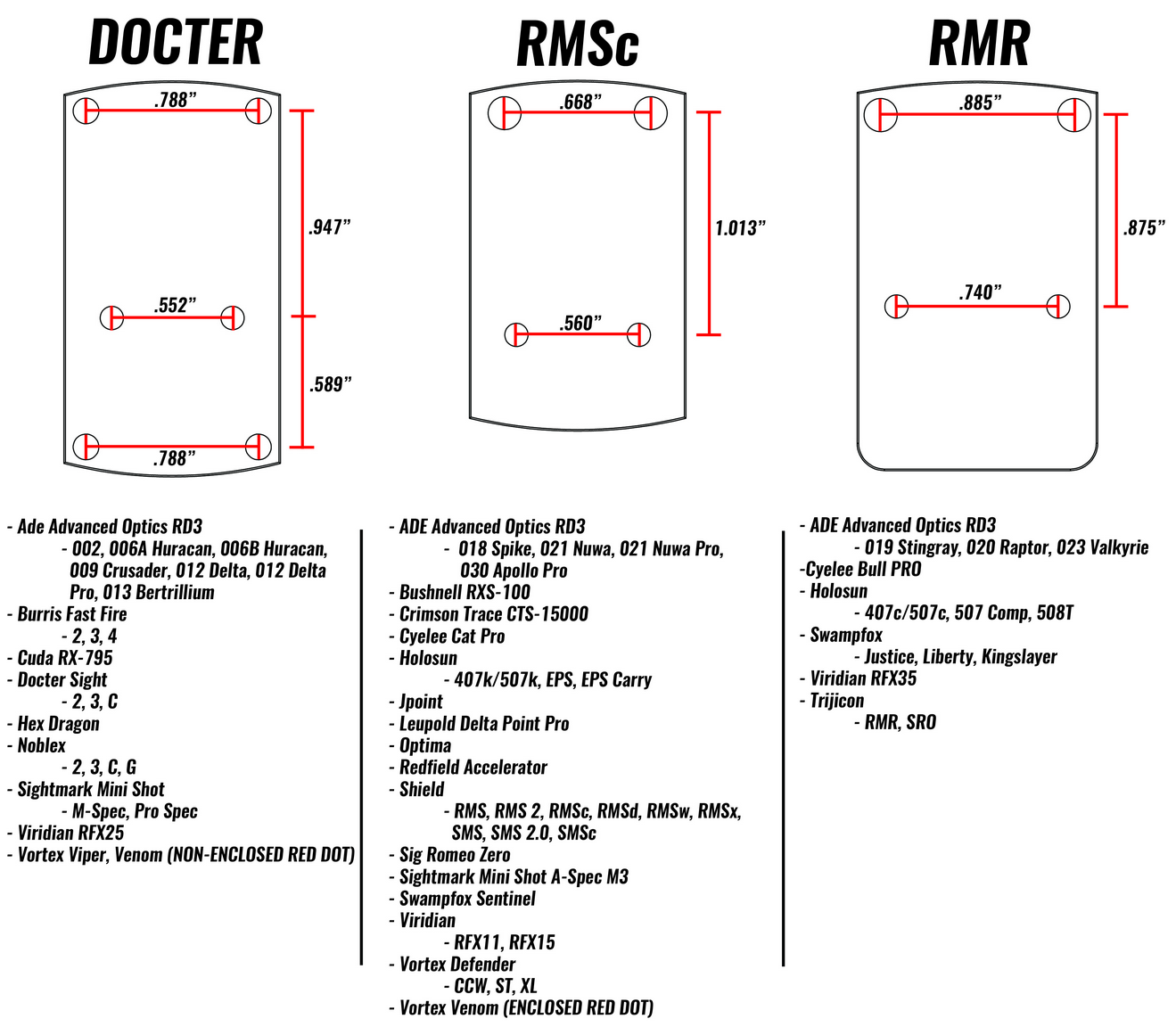

The dominant pistol red dot footprints break down into five main patterns. RMR footprint uses two screws 1.27 inches apart and has become the de facto standard. Most "RMR-compatible" optics use this pattern, including Holosun 407C/507C series, SIG Romeo1 Pro, and dozens of others.

Holosun 407C Deals

Prices may change. May contain affiliate links.

DeltaPoint Pro footprint spreads three screws in a triangle pattern. Leupold created this for their DeltaPoint Pro, but you'll also find it on some SIG Romeo optics and a few others. The three-screw design distributes stress better than two-screw patterns.

Docter/Noblex footprint shows up on smaller optics like the Leupold DeltaPoint Micro and some budget red dots. Two screws sit closer together than RMR pattern, typically around 0.9 inches apart.

Shield RMSc footprint targets micro red dots for subcompact pistols. The Shield RMSc, Holosun 407K/507K, and SIG Romeo Zero use this smaller pattern. Two screws about 0.7 inches apart.

ACRO footprint represents Aimpoint's enclosed design approach. The ACRO P-1 and P-2 use this pattern, along with some Steiner and Primary Arms enclosed optics. Completely different mounting approach from open emitter designs.

Here's what actually matters for compatibility: screw spacing, screw thread pitch, and overall optic dimensions. Two optics can share the same bolt pattern but have different heights or widths that affect holster compatibility or sight picture.

Holosun 507C Deals

Prices may change. May contain affiliate links.

Optic-ready pistol systems

Most modern striker-fired pistols ship with some version of "optic ready" capability. The marketing names vary, but they all cut a recess in the slide and include mounting hardware.

Glock MOS (Modular Optic System) cuts a large rectangular recess and includes multiple adapter plates. The system works, but the included plates sit the optic high and create a gap between optic and slide. Aftermarket plates from C&H Precision, Forward Controls Design, or CHPWS solve the height and sealing issues.

The MOS cut accepts RMR footprint optics directly with the right plate. Glock includes plates for RMR, DeltaPoint Pro, Doctor, and a few others. Problem is, the stock plates use the slide's existing recoil spring assembly holes, which puts stress on the wrong parts of the slide.

Smith & Wesson CORE (Competition Optics Ready Equipment) machines a precise cut for specific footprints. M&P CORE slides typically come cut for one footprint — usually RMR or DeltaPoint Pro. No adapter plates needed, but you're locked into that footprint unless you machine a new cut.

Trijicon RMR Deals

Prices may change. May contain affiliate links.

SIG P320 optic-ready variants use a direct-mount system with no adapter plates. The slide comes cut for RMR footprint optics. Clean installation, proper height, good sealing. SIG got this right from the start.

Springfield XD-M OSP (Optical Sight Platform) uses adapter plates similar to Glock MOS. The cut is smaller and more precise than Glock's, but you still deal with adapter plate limitations. Springfield includes plates for common footprints.

CZ P-10 optic-ready models direct-mount RMR footprint optics. No plates, no fuss. The cut depth puts most optics at the right height for lower-third co-witness with suppressor-height iron sights.

Shadow Systems pistols machine their optic cuts to tight tolerances for direct mounting. Their OR (Optic Ready) models accept RMR footprint optics without adapter plates. The cut quality rivals custom machine work.

Personal experience

I've run the same Holosun 507C on five different mounting systems: Glock MOS with stock plate, Glock MOS with C&H plate, direct-mount on a Shadow Systems slide, direct-mount on an M&P CORE, and a dovetail mount on a non-optic-ready Glock.

The differences are real. Stock Glock MOS plates create a 2-3mm gap between optic and slide. Water, debris, and fouling collect in that gap. The optic sits noticeably higher, changing your sight picture and making holster fit tighter.

Direct-mount systems put the optic closer to the slide, seal better, and usually co-witness properly with iron sights. The sight picture feels more natural because the optic sits lower.

Dovetail mounts work but add bulk and weight. The mount extends behind the slide, affecting balance and holster compatibility. Zero retention depends entirely on the mount quality and installation.

Adapter plates and direct mounting

Adapter plates solve compatibility between your pistol's cut and your optic's footprint. They're necessary when footprints don't match, but they're not all created equal.

Stock manufacturer plates (Glock, Springfield, etc.) prioritize cost over performance. They're usually stamped steel, sit the optic high, and use questionable mounting methods. They work for casual shooting but create compromises.

Aftermarket plates from C&H Precision to Forward Controls Design and others address the stock plate problems. They're machined from aluminum or steel, sit the optic lower, seal better, and use proper mounting points on the slide.

The best adapter plates eliminate the gap between optic and slide. They're thick enough to provide proper thread engagement but thin enough to maintain reasonable optic height. Good plates include O-rings or gaskets for sealing.

Direct mounting eliminates the adapter plate entirely. Your pistol's cut matches your optic's footprint exactly. This gives the lowest profile, best sealing, and most secure mounting. Always choose direct mounting when possible.

Holosun 407K Deals

Prices may change. May contain affiliate links.

Some optics include multiple mounting options. The Holosun 507Comp comes with both RMR and DeltaPoint Pro bolt patterns. You choose which one to use based on your pistol's cut.

Dovetail mounting for non-optic-ready pistols

Your pistol doesn't have an optic cut, but you want a red dot. Dovetail mounts replace your rear sight and provide an optic mounting platform.

Dovetail mounts work by clamping into your existing rear sight dovetail. The mount extends over the slide and provides a platform for your optic. Installation requires removing your rear sight and sliding the mount into place.

The advantages are obvious: no slide machining required, reversible installation, works on any pistol with a rear sight dovetail. You can add a red dot to your carry gun without permanent modifications.

Holosun 507K Deals

Prices may change. May contain affiliate links.

The disadvantages are real. Dovetail mounts add bulk and weight behind the slide. They change the pistol's balance point. Holster compatibility becomes an issue — most holsters won't accommodate the added bulk.

Zero retention depends on the dovetail fit and mount design. Loose dovetails let the mount shift under recoil. Tight dovetails can crack the slide if over-torqued. The mount needs to clamp securely without damaging the slide.

Quality dovetail mounts from Dawson Precision, Novak, or Trijicon use proper materials and tight tolerances. Budget mounts from unknown manufacturers often fail after a few hundred rounds.

The mounting platform needs to be rigid and properly aligned. Flex in the mount translates to zero shift. The platform should place your optic at the right height for co-witnessing with your front sight.

Common mounting mistakes

Wrong footprint compatibility tops the list. You can't force an RMR footprint optic onto a DeltaPoint Pro cut, no matter how similar they look. Check the actual dimensions and screw patterns before ordering anything.

Aimpoint ACRO P-2 Deals

Prices may change. May contain affiliate links.

Using the wrong screws creates problems. Red dot mounting screws have specific thread pitches and lengths. Too long and they bottom out or interfere with internal components. Too short and they don't provide adequate thread engagement. Most optics include the correct screws, but aftermarket plates might require different lengths.

Over-torquing screws cracks optic housings or strips threads. Most red dot mounting screws need 12-15 inch-pounds of torque. That's finger-tight plus a quarter turn with a proper torque wrench. More isn't better.

Ignoring thread locker leads to loose screws and zero shift. Use blue Loctite 243 on mounting screws. Red Loctite makes removal nearly impossible. No thread locker means screws work loose under recoil.

Poor sealing lets water and debris into the optic cut. Stock adapter plates often leave gaps. Aftermarket plates with O-rings or gaskets solve this. Direct-mount installations usually seal better than adapter plate setups.

Mixing metric and standard screws strips threads. Some optics use metric threads (M3 or M4), others use standard threads (#6-32 or #8-32). The threads look similar but aren't interchangeable. Check your optic's manual for the correct thread specification.

C&H Precision Plates Deals

Prices may change. May contain affiliate links.

Pistol and optic compatibility matrix

Here's the actual compatibility between common pistol platforms and red dot footprints:

| Pistol System | Direct Mount | With Stock Plates | With Aftermarket Plates | Best Aftermarket Plates | Cowitness |

|---|---|---|---|---|---|

| Glock MOS (Full/Compact) | None (requires adapter plates) | RMR, DeltaPoint Pro, Doctor, Shield RMSc, Romeo-X | RMR, DeltaPoint Pro, ACRO, Romeo-X, Holosun 407C/507C/508T/509T, EPS | C&H V4, Forward Controls OPF-G, Athena Precision | Suppressor height sights required; Holosun SCS MOS works with stock sights |

| Glock 43X/48 MOS (Slimline) | Shield RMSc footprint (modified) | Shield RMSc, Holosun 407K/507K (modified fit) | RMRcc, Holosun EPS Carry, 407K/507K | C&H V4 Slimline plates | Stock sights may work; suppressor height recommended |

| Smith & Wesson M&P 2.0 Core/OR | M&P9/40 CORE: Direct mount RMR footprint; M&P Shield Plus CORE: Direct mount Shield RMSc footprint | RMR, DeltaPoint Pro (varies by model) | C&H plates for DeltaPoint Pro, ACRO | C&H Precision M&P plates | Suppressor height sights recommended for most setups |

| Sig P320 Optic Ready (M17/M18/Legion/X-Series) | DeltaPoint Pro/Romeo1 Pro footprint (varies by slide version) | Romeo1 Pro, DeltaPoint Pro, limited RMR support on some models | RMR, ACRO, Holosun 509T, 407C/507C/508T, EPS | C&H Precision, Forward Controls OPF-M17, Apex Tactical | Suppressor height sights required; Holosun SCS 320 works with stock sights |

| Sig P365/P365X/P365XL | Shield RMSc footprint (on XMACRO: RMR cut available) | Romeo Zero, Shield RMSc | Holosun 407K/507K, EPS Carry, RMRcc | C&H Precision, DPP Titanium plates | Stock sights work with most micro dots |

| Springfield XD-M OSP | None (requires adapter plates) | RMR, DeltaPoint Pro, Doctor | RMR, DeltaPoint Pro, ACRO, Holosun 407C/507C | C&H Precision, Springfield OEM plates | Stock height sights may work depending on optic |

| Springfield Hellcat/Hellcat Pro | Shield RMSc footprint | Shield RMSc, Hex Wasp, Romeo Zero | Holosun 407K/507K, EPS Carry, RMRcc | C&H Precision Hellcat plates | Stock sights work; suppressor height for larger optics |

| CZ P-10 Optic Ready | RMR footprint only | RMR, Holosun 407C/507C | Limited aftermarket plates available | C&H Precision, CZ Custom | Standard height sights work |

| Shadow Systems OR | RMR footprint only | No adapter plates needed for RMR footprint | No adapter plates needed for RMR footprint | Direct mount - no plate needed | Suppressor height sights recommended |

| HK VP9 OR/VP9L OR | Proprietary cut (requires HK plates) | RMR (Plate #2), DeltaPoint Pro (Plate #1), Doctor (Plate #3), RMSc (Plate #4), ACRO (Plate #5) | RMR, Holosun 407C/507C/508T/509T, ACRO via plates | HK OEM plates, C&H Precision, EGW | Suppressor height sights required; Holosun SCS VP9 works with stock sights |

| Walther PDP 1.0 | Proprietary cut (requires Walther plates) | RMR, DeltaPoint Pro, Vortex Viper/Venom, Doctor, ACRO (via free Walther plates) | Holosun 407C/507C/508T/509T, RMR, ACRO, EPS | C&H Precision, Calculated Kinetics DOGTAG | Stock sights work with most optics |

| Walther PDP 2.0/F-Series | Proprietary cut (requires Walther plates) | RMR, DeltaPoint Pro, ACRO (via free Walther plates) | Holosun 407C/507C/508T/509T, RMR, ACRO, EPS, 407K/507K | C&H Precision, Calculated Kinetics DOGTAG | Stock sights work; Holosun SCS PDP works with stock sights |

| FN 509 MRD/Tactical | FN Low Profile Optics Mounting System (multi-plate) | RMR, DeltaPoint Pro, Vortex Viper/Venom, Doctor, Trijicon SRO (plates included) | Holosun 407C/507C/508T/509T, Shield RMSc, 407K/507K via aftermarket | C&H Precision, Apex Tactical | Suppressor height sights included; excellent cowitness |

| Canik TP9 SFx/Elite Combat | Proprietary cut (requires Canik plates) | RMR (Plate #2), Vortex Venom (Plate included), Doctor, Shield RMSc | Holosun 407C/507C/508T, RMR, 407K/507K | Galloway Precision, Calculated Kinetics DOGTAG | Stock suppressor height sights work well |

| Canik METE Series | Proprietary cut (different from TP9) | RMR, DeltaPoint Pro, Doctor via included plates | Holosun 407C/507C/508T, RMR, 407K/507K | Calculated Kinetics, Galloway Precision | Stock sights work; suppressor height recommended for larger optics |

| Beretta APX A1 | Proprietary cut | RMR, DeltaPoint Pro, Burris FastFire via included plates | Holosun 407C/507C, RMR | Limited aftermarket options | Suppressor height sights recommended |

| Staccato 2011 (DUO/XC/XL) | DUO: Proprietary double-optic cut; Standard: RMR direct | RMR (standard models) | RMR, DeltaPoint Pro, ACRO, Holosun 509T | C&H Precision DUO plates | Standard height sights work on most models |

Key Optic Footprint Reference

| Footprint | Common Optics | Notes |

|---|---|---|

| Trijicon RMR | RMR, RMR HD, SRO, RCR, Holosun 407C/507C/508T/509T/507 COMP, Swampfox Liberty/Justice | Most common footprint; widest aftermarket support |

| Shield RMSc (K-Series) | Shield RMSc/SMS2, Holosun 407K/507K/EPS Carry, Trijicon RMRcc, Sig Romeo Zero | Compact/subcompact optics; Holosun "K" series is slightly modified |

| Leupold DeltaPoint Pro | DeltaPoint Pro, Sig Romeo1 Pro, EOTech EFLX | Common on Sig P320 variants |

| Aimpoint ACRO | ACRO P-1/P-2/C-2, Steiner MPS | Enclosed emitter; requires dedicated plates |

| Doctor/Noblex | Doctor, Noblex Sight III, Vortex Viper/Venom, Burris FastFire | Older standard; still common on budget optics |

Plate Manufacturer Quick Reference

C&H Precision (CHPWS) - Industry standard; widest pistol/optic coverage; V4 plates recommended

Forward Controls Design (FCD) - Premium steel plates; excellent for Glock MOS and Sig P320

Calculated Kinetics - DOGTAG design with brass deflector; great for Walther/Canik

Apex Tactical - Quality plates for FN, Sig, S&W

EGW - Budget-friendly aluminum plates; solid performance

Athena Precision - Premium steel Glock MOS plates

Direct-Mount Optics (No Plate Needed)

These optics are designed to mount directly to specific pistol platforms without adapter plates:

Holosun SCS MOS - Glock MOS (full-size/compact)

Holosun SCS 320 - Sig P320 (DPP footprint)

Holosun SCS PDP - Walther PDP 2.0/F-Series

Holosun SCS VP9 - HK VP9 OR

Holosun SCS Carry - Includes RMSc adapter for subcompacts

SIG P320 Deals

Prices may change. May contain affiliate links.

Red Dot Optic Footprint Reference

Not sure what footprint your optic uses? Find it below, then check the compatibility matrix above to see which pistols support it.

| Footprint | Optics Using This Footprint | Compatible Pistol Platforms | Notes |

|---|---|---|---|

| Trijicon RMR | Trijicon RMR (all variants)Trijicon RMR HDTrijicon SROTrijicon RCRHolosun 407C, 507C, 508T, 509T, 507 CompSwampfox Liberty, JusticePrimary Arms SLx MD-20Riton X3 Tactix PRD | Glock MOS, Sig P320 (w/plate), HK VP9 OR (Plate #2), Walther PDP, FN 509, Canik TP9, CZ P-10, Shadow Systems, Springfield XD-M OSP | Most common footprint with widest aftermarket plate support. The 509T is enclosed emitter but uses RMR mounting holes. |

| Leupold DeltaPoint Pro | Leupold DeltaPoint ProSIG Romeo1 (original)SIG Romeo1 ProEOTech EFLXPrimary Arms SLx MD-25Holosun SCS 320 | Sig P320 (direct on most models), Glock MOS (w/plate), HK VP9 OR (Plate #1), Walther PDP, FN 509 | Factory footprint on most Sig P320 optics-ready slides. SCS 320 designed specifically for this cut. |

| Doctor/Noblex | Docter Optic Red DotNoblex Sight IIIVortex VenomVortex ViperBurris FastFire II, III, 4Sightmark Mini Shot | Glock MOS (w/plate), HK VP9 OR (Plate #3), Walther PDP, FN 509, Canik TP9, Springfield XD-M OSP | Older but still common footprint. Budget-friendly optics typically use this pattern. Vortex Venom/Viper share this footprint despite marketing. |

| Shield RMSc (K-Series) | Shield RMSc, SMS2Holosun 407K, 507KHolosun EPS Carry, SCS CarrySIG Romeo Zero, Romeo Zero EliteSwampfox SentinelTrijicon RMRccSpringfield Hex Wasp | Glock 43X/48 MOS, Sig P365 series, Springfield Hellcat, S&W M&P Shield Plus, HK VP9 OR (Plate #4), Canik TP9 Elite SC | Compact optic footprint for subcompact/micro pistols. Holosun K-series is slightly modified (no rear recoil lugs) but holes align. |

| Aimpoint ACRO | Aimpoint ACRO P-1, P-2, C-2Steiner MPSLead & Steel PB-3 | Glock MOS (w/plate), Sig P320 (w/plate), HK VP9 OR (Plate #5), Walther PDP (w/plate), Staccato | Enclosed emitter design. Requires dedicated ACRO plates - will not fit RMR cuts. Steiner MPS recoil lug may be slightly wider than ACRO. |

| SIG Romeo-X | SIG Romeo-X CompactSIG Romeo-X Pro | Glock MOS (direct with included plate), Sig P320 (w/plate) | SIG's proprietary footprint designed specifically for Glock MOS. Ships with MOS-compatible plate in box. |

| Holosun EPS Full Size | Holosun EPS (full size)Holosun EPS MRS | Ships with RMR adapter plate; fits any RMR-compatible platform with included adapter | Uses K-series (modified RMSc) footprint but includes RMR adapter plate in box. Can also mount direct to K-series cuts. |

| Leupold DeltaPoint Micro | Leupold DeltaPoint Micro | Glock MOS (rear sight dovetail mount), S&W M&P Shield (dovetail) | Unique footprint - mounts in rear sight dovetail rather than traditional optic cut. Not compatible with standard plate systems. |

Quick Footprint Identification Tips

Measure the screw hole spacing: RMR pattern holes are ~1.535" apart; RMSc/K-series are ~0.787" apart

Check for recoil lugs: RMR-pattern optics have front and rear lugs; Holosun K-series lacks rear lugs

Enclosed vs open emitter: ACRO, 509T, and EPS are enclosed; most others are open

When in doubt: Check the manufacturer's spec sheet - footprint is usually listed under "mounting"

Mounting hardware and tools

Red dot mounting requires the right tools and hardware. Most installations need a torque wrench, thread locker, and proper screws.

Torque wrenches prevent over-tightening. A 1/4-inch drive torque wrench with inch-pound measurements works for most red dot installations. Wheeler, Fix It Sticks, and Tekton make good options under $50.

Thread locker secures screws without permanent bonding. Blue Loctite 243 is the standard choice. Apply a small drop to the screw threads before installation. Red Loctite 271 is too strong for red dot mounting — you'll need heat to remove screws later.

Mounting screws vary by optic and installation. Most optics include the correct screws for direct mounting. Adapter plates often require different screw lengths. Keep a selection of common sizes: #6-32 and #8-32 in various lengths, plus M3 and M4 metric screws.

Allen wrenches or Torx drivers fit most mounting screws. T15 Torx fits many Trijicon products. 2mm and 2.5mm Allen wrenches work for most Holosun optics. A quality bit set covers most installations.

Sight pushers help with dovetail mount installation. The mount needs to slide into the dovetail without damaging the slide finish. Brass or nylon punches work for careful installations. A proper sight pusher makes the job easier and safer.

Zeroing and co-witness considerations

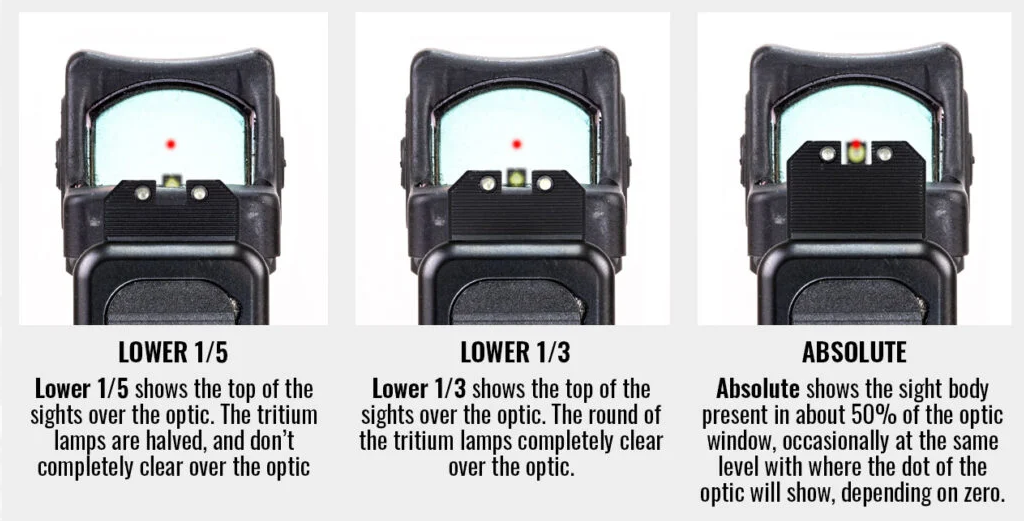

Your mounting choice affects iron sight co-witness. Co-witness means your iron sights are visible through the red dot window and align with the dot.

Shadow Systems OR Deals

Prices may change. May contain affiliate links.

Lower third co-witness puts iron sights in the bottom third of the red dot window. This setup works well for most shooters. You see the dot clearly but have backup iron sights visible. Requires suppressor-height iron sights with most red dot installations.

Absolute co-witness aligns iron sights with the red dot at the same height. The front sight post sits right at the bottom of the red dot window. Some shooters prefer this for consistency between iron sights and red dot shooting.

No co-witness means iron sights and red dot don't align. You might have backup iron sights, but they zero differently than the red dot. This setup works if you plan to remove iron sights entirely.

Mounting height affects co-witness more than anything else. Stock adapter plates usually sit the optic too high for proper co-witness with standard iron sights. Direct mounting or quality aftermarket plates solve this problem.

Holosun 507 Comp Deals

Prices may change. May contain affiliate links.

Your zero process changes with different mounting heights. A higher mounted optic has more offset between bore axis and sight line. This affects point of impact at different distances, especially close range.

Troubleshooting mount problems

Zero shift after installation usually means loose mounting screws or a flexing mount. Check screw torque first — most red dot screws need 12-15 inch-pounds. Use thread locker on all mounting screws.

Optic sits too high for holster compatibility. Stock adapter plates are often the culprit. Aftermarket plates sit lower and improve holster fit. Direct mounting eliminates the problem entirely.

Water or debris in the optic cut indicates poor sealing. Stock adapter plates often leave gaps around the optic. Aftermarket plates with O-rings or gaskets seal better. Clean the cut and plate surfaces before installation.

Screws won't tighten properly suggests wrong thread pitch or damaged threads. Don't force mismatched screws. Check your optic manual for correct thread specifications. Damaged threads in the slide require professional repair.

Novak Dovetail Mount Deals

Prices may change. May contain affiliate links.

Optic doesn't sit flush on the mount. Check for debris in the optic cut or on the mounting surfaces. Some optics have raised areas around the mounting holes that prevent flush seating. This is normal if the optic functions properly.

Battery compartment won't open with the optic mounted. Some mounting setups interfere with battery access. Holosun side-loading batteries solve this problem. Top-loading designs might require optic removal for battery changes.

What to do next

Start by identifying your pistol's mounting system and your optic's footprint. Check manufacturer websites or measure the bolt patterns yourself. Don't assume compatibility based on marketing names or similar appearances.

If you have an optic-ready pistol, determine whether you need an adapter plate or can direct mount. Direct mounting is always preferable when possible. If you need an adapter plate, buy a quality aftermarket option rather than using stock plates.

For non-optic-ready pistols, decide between slide machining and dovetail mounting. Slide machining gives better results but costs more and is permanent. Dovetail mounting is reversible but adds bulk and weight.

Order the correct mounting hardware before starting installation. Most optics include screws for direct mounting, but adapter plates often require different lengths. Get blue thread locker and a proper torque wrench if you don't have them.

Plan your iron sight setup before mounting the optic. Determine what co-witness you want and whether you need suppressor-height sights. Order sights and optic together to avoid multiple installations.

Test your setup thoroughly after installation. Start with close-range zeroing, then confirm zero at your intended shooting distance. Check screw torque after the first 50-100 rounds, then periodically during regular shooting.

The mounting system matters as much as the optic itself. A great red dot on a poor mount will disappoint you. A decent red dot on a solid mount will serve you well. Get the mounting right first, then worry about optic upgrades later.