You're staring at a 6x8 space thinking it's too small for reloading. That's backwards. Small spaces force you to think through every square inch, and honestly, most reloaders waste half their bench space anyway. I've loaded thousands of rounds in spaces smaller than most people's walk-in closets.

The key isn't cramming everything in—it's building smart from the start. Every component placement matters when you're working with 48 square feet. Get the workflow wrong and you'll be reaching over powder cans to grab brass, or worse, trying to seat bullets while your press vibrates the scale table.

Here's what actually works: build around your press first, plan storage second, and leave room to actually work. Most bench plans start with dimensions and end up with a glorified shelf. We're going the other direction.

Press placement drives everything else

Your press goes in the corner. Not the middle, not along a wall—the corner. This gives you the most leverage for heavy operations while using the least bench real estate. Mount it 6-8 inches from both walls so you can get your whole body behind tough cases.

The press needs to sit at the right height for your stroke. Stand normally and let your arms hang. Your knuckles should clear the bench top by 2-3 inches when the press handle is at the bottom of its stroke. Most guys build their bench too high because they're thinking about sitting. You'll do 90% of your pressing standing up.

Bench thickness matters more in small spaces because you can't brace against a wall. Use 2x10 construction lumber for the top, not plywood. The extra mass dampens vibration and the thickness gives you solid mounting for heavy equipment. I've seen too many thin benches that flex every time you size a case.

Mount your press on a steel plate if you're going progressive later. A 12x12 inch piece of quarter-inch steel distributes the load and makes swapping presses easier. Bolt it through the bench top with carriage bolts—the smooth heads won't catch brass or components.

The work triangle that actually works

Think about your hands during a typical loading session. You're moving between the press, the scale, and component storage constantly. In a 6x8 space, these three points form a triangle with sides no longer than arm's reach.

Press in the corner, scale 18 inches to the right on the same surface level. Any farther and you're walking between operations. Any closer and press vibration affects your powder throws. The scale needs its own dedicated section of bench—not a shelf, not a separate table that's the wrong height.

Component storage goes on your weak-side wall within easy reach of the press. Bullets in the top drawer, brass in the middle, primers in the bottom. This keeps the heaviest items lowest and puts the most-handled components at the best working height.

What you don't need: a separate priming station, a dedicated case prep area, or multiple work surfaces at different heights. These eat space without adding efficiency in a small setup.

Bench construction for the space

Build an L-shaped bench that uses both walls. The long leg runs 6 feet along one wall, the short leg extends 3 feet along the adjacent wall. This gives you 21 square feet of work surface in a 48 square foot room—nearly half your floor space working for you.

Frame it with 2x4s on 16-inch centers. The corner where the two legs meet needs extra support—add a diagonal brace underneath. This corner carries your press loads and gets the most stress.

The bench top needs to be one continuous surface, not two pieces joined at the corner. Use a single piece of 2x10 lumber ripped to width, or laminate two pieces with construction adhesive and screws every 6 inches. Joints at the corner create weak spots that develop gaps over time.

Height depends on your build, but 36 inches works for most people between 5'8" and 6'2". Shorter guys go to 34 inches, taller to 38 inches. Test this before you build—stack lumber to the proposed height and run through press motions with a stick the length of your press handle.

Storage that doesn't waste space

Forget about storing components on the bench top. Every square inch of surface needs to be available for actual work. Build storage into the bench structure instead.

The space under the long leg becomes your component storage. Install drawer slides rated for 100 pounds—powder and bullets add up fast. Three drawers: bullets on top (most accessed), brass in the middle (heaviest), primers on the bottom (safest location).

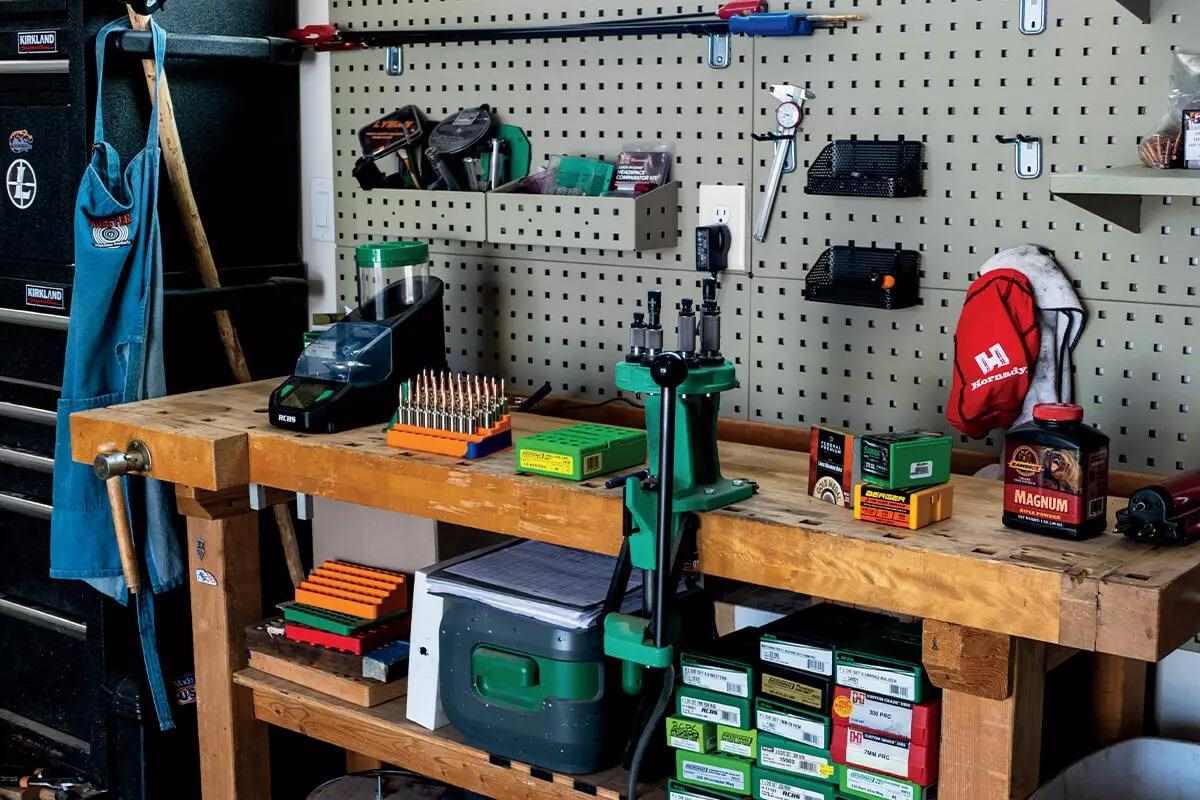

Use the wall space above the bench for tools and gauges. A simple pegboard system keeps everything visible and accessible. Mount it 18 inches above the bench surface so you're not hitting your head but can still reach everything easily.

Powder storage goes in a separate cabinet, not integrated into the bench. Build or buy a cabinet that sits on the floor next to your bench. This keeps powder containers at a comfortable height for pouring and isolates them from any bench vibration.

Bench notes: what you'll actually use daily

After loading in small spaces for years, here's what gets used every session: press, scale, powder measure, calipers, case lube pad, and a small parts tray. Everything else is periodic use.

Your daily tools need dedicated spots within arm's reach of the press. I cut a shallow tray into the bench top 12 inches from the press—just deep enough for calipers and small tools. This keeps them from sliding around but doesn't take up vertical space.

The parts tray sits between the press and scale. A simple aluminum baking pan works perfectly. It catches dropped primers, holds cases during batch operations, and gives you a clean surface for small parts.

Case lube goes on a pad mounted to the bench edge. You'll lube cases constantly, so make it convenient. A simple wooden block with a felt pad glued on top, screwed to the bench edge where your weak hand naturally falls.

Equipment comparison for tight spaces

Single stage presses: RCBS Rock Chucker Supreme takes up the least bench space while handling everything from .223 to .338 Lapua. The Redding Boss is more compact but costs twice as much. Lee Classic Cast is the budget option but needs more frequent adjustment.

Progressive presses: Dillon 550 fits in the smallest footprint if you're planning to upgrade later. The Hornady Lock-N-Load AP needs more depth but handles primer feeding better. Skip the Lee progressive presses in tight spaces—they need too much room for case feeders and bullet tubes.

Scales: RCBS ChargeMaster Lite gives you electronic convenience in the smallest package. The older ChargeMaster 1500 is more accurate but takes up 30% more bench space. Beam scales like the RCBS 10-10 are compact but slow for volume loading.

Powder measures: Hornady Lock-N-Load measure mounts directly to most presses, saving bench space. The RCBS Uniflow needs a separate mount but throws more consistent charges. Lee measures are compact but require more adjustment between powders.

Calipers: Mitutoyo digital calipers in the 6-inch size. Longer calipers don't fit comfortably in small spaces, shorter ones limit what you can measure. Digital readout saves time over dial calipers when you're working in tight quarters.

Common mistakes that kill efficiency

Building the bench too deep. Anything more than 24 inches deep creates dead space you can't reach comfortably. You'll end up stacking junk in the back that never gets used.

Mounting the press too close to the wall. You need clearance behind the press for your body position and leverage. Six inches minimum, eight is better. I've seen guys mount presses 2 inches from the wall then wonder why they can't get good leverage on stuck cases.

Using the wrong bench height. Most plans call for standard table height (30 inches) or kitchen counter height (36 inches). Neither is right for press work. Test the height with your actual press before building.

Inadequate component organization. Throwing everything in random drawers wastes time and creates safety issues. Mixed primers, unlabeled powder containers, and loose bullets slow down every operation.

Ignoring powder storage requirements. Powder containers need ventilation and temperature control. Stuffing them under a bench in a corner creates condensation problems and makes inventory difficult.

Workflow optimization for small spaces

Plan your operations in batches that minimize tool changes. Size all your cases, then prime all your cases, then charge all your cases. This reduces the number of times you're swapping equipment and reaching for different tools.

Keep a loading log mounted to the wall above your scale. A simple clipboard works fine. Track charge weights, bullet seating depths, and case counts for each session. In a small space, you can't afford to lose track of where you are in a batch.

Set up a simple quality control station at the end of your bench. This is just a space for final case gauging and visual inspection before boxing loaded rounds. A small parts tray and a case gauge holder mounted to the bench edge.

Use the wall space behind your press for reference materials. Mount a small shelf for your loading manuals and a magnetic strip for frequently used hex keys and small tools.

The reality of loading in 48 square feet

You'll load slower than someone with a dedicated room, but not by much. The key is accepting that you can't have every tool and gadget within reach. Focus on the essentials and batch your operations efficiently.

Most of your time gets spent on case prep anyway—sizing, trimming, deburring. These operations don't need much space, just good organization. A small space forces you to develop consistent habits because there's no room for sloppy technique.

The biggest advantage of a small setup is that everything stays clean and organized by necessity. You can't let brass pile up or leave powder measures uncapped because there's nowhere for the mess to hide.

Start with the bench and press mount. Get those right and everything else falls into place. Most reloading problems in small spaces come from trying to cram too much in rather than building smart from the beginning.