Your AR shoots okay, but you want it to shoot great. You've heard about precision barrels and adjustable gas blocks, and now you're wondering if threading a barrel and tuning the gas system is something you can tackle yourself. Here's the thing: these aren't beginner jobs, but they're not black magic either. With the right tools and patience, you can transform a decent rifle into a precision shooter.

The key is understanding what you're actually trying to accomplish. Threading a barrel isn't just about adding a suppressor mount — it's about creating a perfectly concentric crown that won't affect accuracy. Gas system tuning isn't just about reducing recoil — it's about finding the minimum gas pressure needed for reliable cycling while maximizing accuracy and extending component life. Get both right, and you'll have an AR that shoots better and runs smoother than most factory rifles.

Before you start, know this: you'll need specific tools, a steady hand, and the ability to measure precisely. If you're the type who eyeballs measurements or rushes through setups, take this work to a professional. One mistake with the threading lathe or gas port drilling can turn an expensive barrel into scrap metal.

Understanding barrel threading fundamentals

Most AR-15 barrels come with either 1/2x28 threads for .223/5.56 or 5/8x24 threads for larger calibers. The first number is the diameter, the second is threads per inch. What matters for precision work is that these threads are cut perfectly concentric to the bore and perpendicular to the barrel's axis. Even a few thousandths of runout will send your groups sideways.

The threading process requires a lathe capable of holding tight tolerances. You'll need a 4-jaw chuck to dial in the barrel, a steady rest for longer barrels, and threading tools sharp enough to cut clean threads without chatter. The barrel needs to be indicated to less than 0.001" runout at both ends before you make the first cut. This isn't a drill press job — you need a proper lathe with good rigidity.

Here's what actually happens during the threading process: you're removing material from the muzzle end while maintaining perfect concentricity with the bore. The threads themselves need to be cut to specific dimensions — too tight and suppressors won't thread on smoothly, too loose and you'll have timing issues with muzzle devices. Most smiths aim for a class 2B thread fit, which provides good engagement without binding.

The crown is equally critical. A precision crown needs to be cut at exactly 90 degrees to the bore, with all edges perfectly uniform. The 11-degree target crown is popular because it protects the critical edge while providing consistent gas release. Some builders prefer a recessed crown for maximum protection, but either works if executed properly.

Gas system length and port sizing

Gas system length affects everything about how your AR runs. Carbine-length systems are short and violent — they work, but they beat up components and create more recoil. Mid-length systems are the sweet spot for most 16-inch barrels, providing smoother cycling and better accuracy. Rifle-length systems are gentlest of all but require longer barrels to function properly.

The gas port size determines how much pressure reaches your bolt carrier. Factory ports are often oversized to ensure function with dirty ammunition and varying conditions. For precision work, you want the minimum port size that still cycles your heaviest loads reliably. This reduces bolt velocity, extends brass life, and often improves accuracy by reducing barrel harmonics disruption.

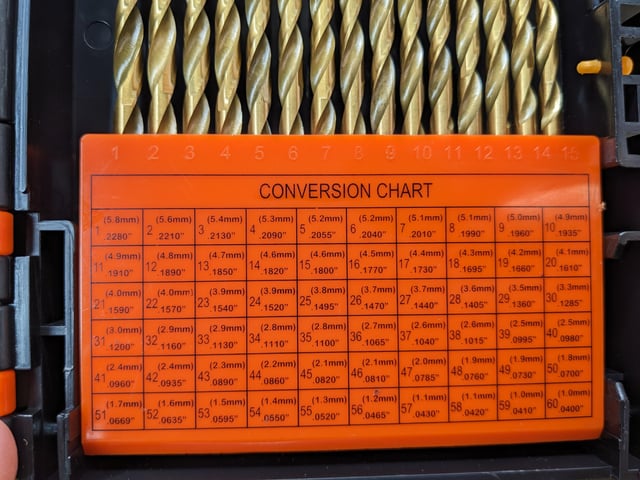

Port sizes vary by gas system length and barrel profile. A typical carbine system might use a 0.093" port, while a mid-length system can often work with 0.086" or smaller. The key is testing with your specific ammunition and buffer system. Start conservative — you can always open up a port, but you can't make it smaller without welding and re-drilling.

Gas port location matters too. The port needs to be drilled perpendicular to the bore and positioned correctly for your gas system length. Carbine systems place the port about 7 inches from the chamber, mid-length around 9 inches, rifle-length around 12 inches. Get the location wrong and you'll have cycling issues no matter what port size you use.

Choosing and installing adjustable gas blocks

An adjustable gas block gives you precise control over gas flow, letting you tune for different loads and shooting conditions. The two main types are restriction blocks that reduce gas flow and bleed-off blocks that vent excess gas. Both work, but bleed-off designs like the Superlative Arms unit tend to run cleaner since they don't trap carbon in the gas tube.

Installation requires careful alignment. The gas block needs to be perfectly centered over the gas port — even slight misalignment will cause function issues. Most precision builders use a gas block alignment jig or indicate the block on a lathe before final installation. The set screws or clamp mechanism needs enough torque to prevent movement under recoil, but not so much that it deforms the barrel.

Here's the installation process: first, ensure your barrel is properly headspaced and the gas port is correctly sized and located. Slide the gas block over the barrel and align it with the gas port using your preferred method. Install the gas tube, making sure it seats fully in both the gas block and upper receiver. Tighten the gas block hardware to specification — typically 15-20 inch-pounds for set screws, following manufacturer specs for clamp-style blocks.

The adjustment process starts with the gas block fully closed. Load a single round and fire. If the bolt doesn't lock back, open the adjustment one click and repeat. Continue until the bolt locks back reliably, then add one or two more clicks for reliability margin. Test with different ammunition weights — heavier bullets typically need slightly more gas.

Barrel selection for precision builds

Not all barrels are created equal for precision work. Look for barrels made from quality steel like 416R stainless or 4150 chrome moly with proper stress relief. The manufacturing process matters — button-rifled barrels are generally more affordable, while cut-rifled barrels often show better consistency but cost more.

Profile affects both weight and heat dissipation. Heavy profiles like HBAR or bull barrels resist heat-induced point of impact shifts but add weight. Medium profiles like the government or pencil profiles save weight but may show more thermal drift during rapid fire. For precision work, a medium-heavy profile often provides the best balance.

Twist rate needs to match your intended ammunition. The common 1:7 twist stabilizes heavy bullets well but may over-stabilize light bullets, potentially affecting accuracy. A 1:8 twist is more versatile, handling everything from 55-grain to 77-grain bullets effectively. Match your twist rate to your primary ammunition choice.

Chamber dimensions affect both accuracy and reliability. A match chamber with minimum headspace and throat dimensions will often shoot better but may not feed all ammunition reliably. A standard 5.56 chamber provides better reliability with military ammunition but may not extract maximum accuracy from match loads. Consider your primary use when selecting chamber specifications.

Threading process and tooling requirements

Threading a barrel requires specific equipment and skills. You'll need a lathe with sufficient swing and bed length, a 4-jaw chuck for precise centering, and a steady rest for longer barrels. The threading tools need to be sharp and properly ground for the thread pitch you're cutting. Cutting oil is essential to prevent work hardening and ensure smooth threads.

The process starts with indicating the barrel in the lathe. Mount the barrel in the 4-jaw chuck and use a dial indicator to check runout at both ends. Adjust the chuck jaws until runout is less than 0.001" — this is critical for concentric threads. Support longer barrels with a steady rest positioned near the muzzle.

Face the muzzle end square before threading. This ensures your threads will be perpendicular to the bore. Take light cuts to avoid work hardening the steel. Most barrels thread easily, but some stainless steels can be gummy and require sharp tools and proper cutting speeds.

Cut the threads in multiple passes, checking fit frequently with a thread gauge or muzzle device. The final pass should leave threads that engage smoothly without binding. A properly threaded barrel should allow a suppressor or muzzle device to thread on by hand for most of its engagement, requiring only light wrench pressure for the final tightening.

Gas port modification techniques

Modifying gas ports requires precision drilling equipment and careful measurement. The port needs to be drilled perpendicular to the bore axis and positioned correctly for your gas system length. Use a drill press with a good vise or, better yet, a milling machine for precise control.

Start by marking the port location based on your gas system length. Measure from the bolt face with the bolt closed — carbine systems typically place the port 7.5 inches forward, mid-length around 9.5 inches. Use a center punch to mark the exact location, then drill a pilot hole with a small bit to establish location.

Drill the final port size in steps, starting smaller and working up. This prevents the bit from wandering and ensures a round hole. Use cutting oil and moderate speed to prevent work hardening. The final hole should be smooth and round — any irregularities will affect gas flow and potentially cause function issues.

Port size affects everything about how your rifle cycles. Start conservative and test thoroughly. A port that's slightly too small is better than one that's too large — you can always open it up, but closing it down requires welding and re-drilling. Keep detailed records of what sizes work with which loads and buffer combinations.

Bench notes: measuring and testing

Precision work requires precision measurement. You'll need quality calipers, thread pitch gauges, and a good dial indicator setup. When checking barrel runout, support the barrel properly and take measurements at multiple points. Even a few thousandths of runout can affect accuracy, especially with suppressed rifles.

Testing threaded barrels requires shooting both suppressed and unsuppressed to check for point of impact shifts. A properly threaded barrel should show minimal shift — typically less than 1 MOA between configurations. Larger shifts indicate concentricity problems that may require rework.

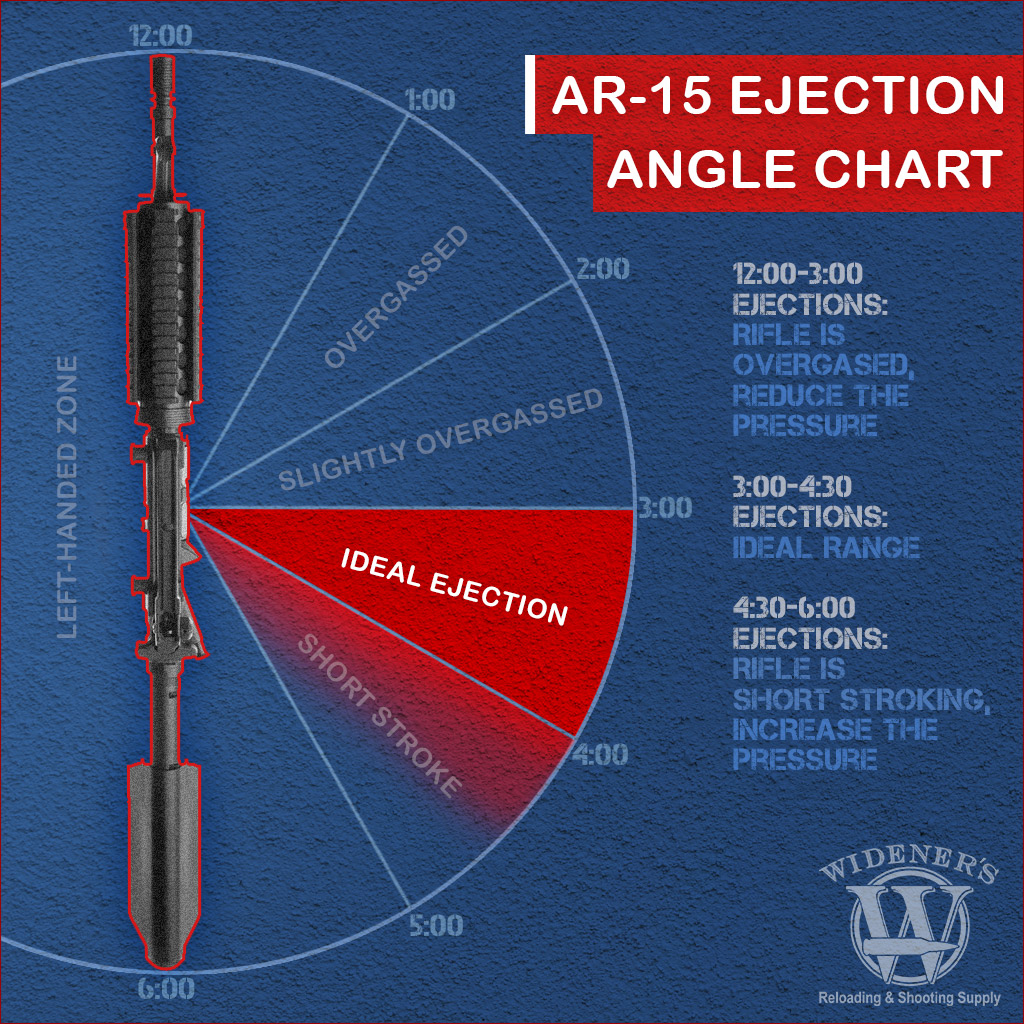

Gas system tuning shows up on the brass. Over-gassed rifles will throw brass far forward and show ejector marks on case heads. Properly tuned rifles drop brass in a consistent pattern near the firing position. Under-gassed rifles may not extract fully or fail to lock the bolt back on empty magazines.

Keep detailed records of your testing. Note ammunition type, gas block settings, buffer weights, and group sizes. This data helps you understand what works with your specific combination and makes future tuning much easier. What works perfectly with one load may need adjustment for different bullet weights or powder charges.

Common mistakes and troubleshooting

The biggest mistake is rushing the setup process. Taking time to properly indicate the barrel and ensure everything is square pays dividends in the final product. I've seen too many barrels ruined by trying to cut threads without proper setup — the threads end up crooked and the barrel becomes scrap.

Threading too aggressively causes work hardening and poor surface finish. Take light cuts and use plenty of cutting oil. If the threads start looking rough or the cutting becomes difficult, you're probably pushing too hard. Back off and take lighter passes.

Gas port location errors are hard to fix. Double-check your measurements before drilling. The port needs to align with your gas block, and the gas block needs to align with your gas tube. Get any part of this chain wrong and you'll have function problems that are difficult to diagnose.

Over-adjusting the gas system is common with new adjustable blocks. Start with minimal gas and work up slowly. It's tempting to add extra clicks "for reliability," but over-gassed rifles are hard on components and often less accurate. Find the minimum that works reliably and stick with it.

Ignoring barrel harmonics leads to inconsistent accuracy. Even perfectly machined components can shoot poorly if the barrel harmonics are disrupted. This is where load development becomes critical — find the combination of bullet weight, powder charge, and gas setting that works together for your specific barrel.

Tools and parts selection

For threading, you'll need a quality lathe with good rigidity. Import lathes can work but often require upgrades to achieve the precision needed for this work. American-made lathes like South Bend or Clausing are excellent choices if you can find them used. The lathe needs sufficient swing to handle barrel profiles and enough bed length for longer barrels.

Threading tools matter more than you might think. Cheap tools will work harden quickly and produce poor surface finishes. Quality carbide tools stay sharp longer and produce better threads. For occasional use, high-speed steel tools work fine if kept sharp.

Gas block selection depends on your specific needs. Wojtek Weaponry makes excellent adjustable blocks with precise click adjustments. Superlative Arms bleed-off blocks run cleaner but cost more. For fixed blocks, quality manufacturers like Daniel Defense or BCM provide reliable options that won't shift under recoil.

Barrel selection affects everything downstream. Criterion makes excellent precision barrels with consistent quality. Faxon offers good value in their Gunner profile barrels. For ultimate precision, custom barrel makers like Bartlein or Krieger provide match-grade options but at significantly higher cost.

Function testing and final adjustments

After completing the threading and gas system work, thorough function testing is essential. Start with single-shot testing to verify basic function, then move to magazine-fed testing with various ammunition types. The rifle should cycle reliably with your intended loads while showing minimal signs of over-gassing.

Accuracy testing reveals whether your work improved the rifle's precision. Shoot groups both suppressed and unsuppressed to check for point of impact consistency. A properly executed precision build should show improved accuracy over the original configuration, especially with quality ammunition.

Gas system tuning may require several range sessions to optimize. Different ammunition weights and powder charges may need slight adjustments to the gas block setting. Keep notes on what works best with each load — this information becomes valuable for future tuning sessions.

Look for signs of proper function during testing. Brass should eject consistently in a tight pattern. The bolt should lock back reliably on empty magazines. Case head markings should be minimal, indicating proper extraction timing. Over-gassed rifles show heavy ejector marks and may crack case necks prematurely.

When to call a professional

Some aspects of this work require professional equipment and experience. If you don't have access to a quality lathe or lack experience with precision machining, barrel threading should be left to a qualified gunsmith. The cost of having it done professionally is often less than the cost of replacing a ruined barrel.

Complex gas port modifications, especially on expensive barrels, are best handled by professionals. A gunsmith with experience in AR platform work will have the proper tooling and knowledge to avoid costly mistakes. The time saved and risk avoided often justify the expense.

Headspace and timing issues require professional attention. If your build doesn't pass basic function checks or shows signs of timing problems, stop shooting and consult a qualified gunsmith. Continuing to fire a rifle with timing issues can cause dangerous failures and expensive damage.

Honestly, if you're not completely confident in your machining skills and don't have proper equipment, consider having the work done professionally. A good gunsmith can thread a barrel and tune the gas system for less than the cost of the tools needed to do it once. The results will be better, and you'll have someone to call if problems develop later.

The satisfaction of building a precision AR yourself is significant, but safety and reliability come first. Know your limits, invest in quality tools if you're going to do the work yourself, and don't hesitate to seek professional help when needed. A properly built precision AR will serve you well for years and provide the accuracy you're seeking.