Understanding the impact of seating depth on .30-06 Springfield performance

The .30-06 Springfield is a versatile cartridge, widely used for hunting and target shooting. Its performance can be influenced by various factors, one of the most significant being seating depth. This article delves into how adjustments in seating depth affect the overall performance of the .30-06 Springfield, focusing on accuracy, pressure signs, and consistency.

Before we dive deeper, it’s essential to emphasize that published data and manufacturer guidance should always be the primary reference when reloading. This discussion adds context and process to help you understand how seating depth can affect your loads.

The role of seating depth

Seating depth refers to how deep the bullet is positioned within the case neck. This depth influences various aspects of ammunition performance, including:

Pressure levels: Changing the seating depth can alter the pressure generated during firing. A deeper seated bullet typically increases pressure, while a shallower seat may decrease it.

Accuracy: The relationship between bullet jump and barrel engagement can impact group size. Properly tuning seating depth can enhance accuracy.

Velocity: Seating depth can also affect the velocity of the round, which in turn influences trajectory and terminal performance.

Understanding these factors will help you make informed decisions about your reloading practices.

Safety first

Before making any adjustments to your loads, ensure you are following safe reloading practices:

Always consult reputable reloading manuals and data.

Wear eye protection and keep your workspace tidy.

Use only one powder at a time on your bench.

Document every change you make to your loads for future reference.

By prioritizing safety, you can focus on refining your loads without unnecessary risks.

Measuring COAL and CBTO

When discussing seating depth, two terms often come up: COAL (Cartridge Overall Length) and CBTO (Cartridge Base to Ogive).

COAL is the total length of the cartridge from the tip of the bullet to the base of the cartridge case. It includes the bullet’s shape and can vary significantly depending on the bullet type.

CBTO measures from the base of the bullet (ogive) to the base of the cartridge case. This measurement is particularly useful for understanding how far the bullet will jump before engaging the rifling.

Both measurements play a critical role in determining effective seating depth for optimal performance.

Steps for adjusting seating depth

When adjusting seating depth for .30-06 Springfield loads, follow these methodical steps:

1. Inspect your components

Start by inspecting your brass, bullets, and primers. Ensure everything is clean and free of defects. Look for signs of wear on your brass, as this can influence pressure and performance.

2. Prep your brass

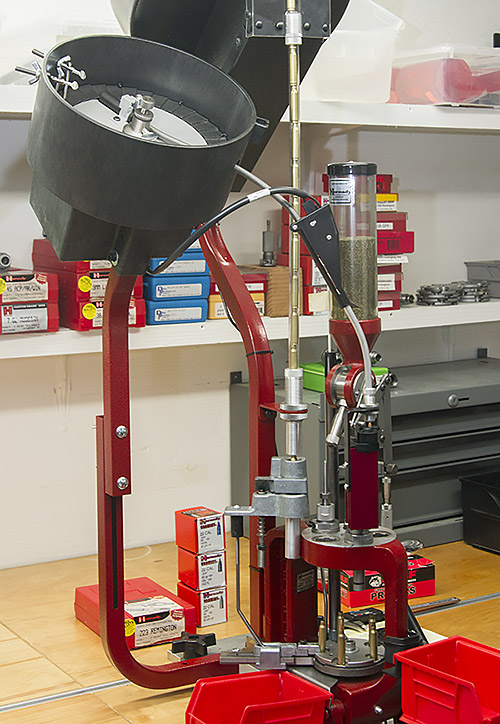

Proper brass preparation is crucial for consistent performance. Resize your brass using a full-length die to ensure proper chamber fit. Trim the cases to a uniform length if necessary, as variations can affect pressure.

3. Measure your current COAL and CBTO

Using a caliper, measure the COAL of your current load. Record this number for reference. Next, measure CBTO by using a comparator tool that allows you to measure from the base of the cartridge case to the ogive of the bullet.

4. Determine your target seating depth

Consult published data to find recommended COAL ranges for your chosen bullet type. Once you have a baseline, decide how much you want to adjust your seating depth based on your goals—whether it’s improving accuracy or managing pressure.

5. Adjust your die

Set up your bullet seating die according to your desired COAL or CBTO. Make small adjustments, typically no more than 0.010 inch at a time, to ensure you don’t overshoot your target depth.

6. Load test batches

Prepare several test batches with varying seating depths. For instance, if your baseline COAL is 3.340 inches, consider creating batches at 3.330, 3.340, and 3.350 inches.

7. Label and log

Label each batch clearly with its COAL or CBTO measurement, along with other relevant details such as powder charge, primer type, and date loaded. Maintaining detailed records will help you analyze performance later.

8. Test at the range

Once you have your test batches ready, head to the range for testing. Focus on measuring both accuracy and pressure signs as you fire each batch.

Observing pressure signs

When adjusting seating depth, it's vital to remain vigilant about pressure signs. Here are some common indicators:

Cratered primers: A sign that pressure may be too high; cratering occurs when the primer cup is pushed back against the firing pin.

Sticky extraction: If you have difficulty extracting spent cases, it may indicate excessive pressure.

Case head expansion: Measure case head expansion after firing; if it exceeds published limits, consider backing off your load.

If you notice any of these signs, it's wise to revert to a more conservative load or adjust your seating depth.

The impact of bullet jump

Bullet jump refers to the distance a bullet travels before it contacts the rifling in the barrel upon firing. This distance can significantly affect accuracy:

Shorter jumps: When bullets are seated closer to the rifling (i.e., deeper), they can engage with more consistency. This often results in improved accuracy but comes with potential risks regarding pressure.

Longer jumps: Seating bullets further away from the rifling may lead to reduced pressure but can sometimes result in larger groups due to inconsistencies in engagement.

Testing different jumps through varied seating depths will allow you to find an optimal balance for your specific rifle and load combination.

Analyzing results

Once you've completed your testing at the range, it's time to analyze your results:

Group sizes: Compare group sizes between different seating depths. Look for patterns indicating which depth yielded tighter groups.

Velocity consistency: Use a chronograph to measure velocity for each batch. Pay attention to standard deviation (SD) and extreme spread (ES) numbers; lower values indicate better consistency.

Pressure signs: Revisit any pressure signs noted during testing and cross-reference them with your load adjustments.

This analysis will provide insight into how effective your adjustments were and guide future modifications.

Common mistakes

Here are some typical mistakes reloaders make regarding seating depth adjustments and how to avoid them:

Ignoring COAL specifications: Failing to adhere to recommended COAL ranges can lead to dangerous pressures or feeding issues in semiautomatic rifles.

Making drastic changes: Sudden large adjustments in seating depth can create unpredictable results; always adjust in small increments.

Neglecting documentation: Not keeping thorough records makes it difficult to analyze what worked or didn’t work over time.

Overlooking pressure signs: Ignoring early signs of pressure issues can lead to dangerous situations; always be cautious and responsive.

By avoiding these pitfalls, you’ll set yourself up for more successful load development.

Range Notes

It’s essential to note that adjustments in seating depth do not exist in isolation; they interact with other factors like powder choice, primer type, and even environmental conditions. Always be prepared for variability and remain flexible in your testing approach. Each rifle may react differently to changes in seating depth, so patience and persistence are key components of successful reloading.

Checklist for adjusting seating depth

Inspect brass, bullets, and primers thoroughly.

Resize and trim brass as needed for uniformity.

Measure initial COAL and CBTO accurately.

Research recommended COAL ranges for chosen bullets.

Make small adjustments to die settings for desired seating depth.

Load multiple test batches with varied depths.

Clearly label all test batches for tracking purposes.

Test at the range while monitoring accuracy and pressure signs.

Conclusion

Understanding how seating depth impacts .30-06 Springfield performance is essential for achieving consistent results at the range or in the field. By methodically adjusting seating depths while maintaining a close eye on safety and performance metrics, you can refine your loads effectively.

Take time with each load development session; thoughtful experimentation will yield improvements over time. Remember that reloading is as much about precision as it is about patience.