Understanding pressure signs: diagnosing common issues in reloaded ammunition

Reloading ammunition is an intricate process that requires precision, attention to detail, and a strong understanding of the components involved. Among the many variables at play, recognizing pressure signs is crucial for ensuring safety and optimizing performance. In this article, we will delve into how to identify common pressure signs in reloaded ammunition and address the potential issues they indicate.

We'll focus on the various pressure signs you may encounter, the causes behind them, and how to respond effectively. Remember, published data and manufacturer guidelines are your primary authorities; my role here is to add context and process, not to replace established load data.

Understanding pressure signs

Pressure signs occur when the pressures generated during the firing of a round exceed acceptable levels. These signs can manifest physically on the brass, primer, or even the firearm itself. It's essential to understand these indicators to prevent potential malfunctions or dangerous situations.

Common pressure signs

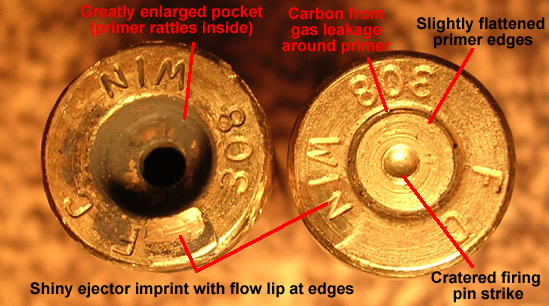

- Flattened primers: When pressures rise, the primer may become flattened against the bolt face. A primer that appears excessively flat compared to others in your batch is a red flag.

- Cratered primers: This occurs when the firing pin crushes the primer material into the firing pin hole. Look for a small indentation or crater around the firing pin mark. This can indicate high pressure, especially if it occurs alongside other signs.

Bilateral bulging: If you observe bulges on both sides of the case near the base, this may suggest overpressure conditions. The case walls are pushed outward by excessive force during ignition.

Case head separation: This occurs when the case head separates from the body of the cartridge due to excessive pressure or wear. Inspect your brass after firing; if you notice any separations, it’s critical to investigate further.

Flattened primers are a clear indicator of excessive pressure during firing. This image highlights the difference between a normal primer and one that has been flattened, emphasizing the importance of recognizing such signs for safe reloading practices. Sticky extraction: If you experience difficulty in extracting spent cases from your chamber, it could indicate high pressures. Excessive pressure can cause cases to expand more than usual, sticking in the chamber.

Increased bolt lift: In firearms with a bolt action mechanism, increased resistance when lifting the bolt can signal elevated chamber pressures. You should always be attentive to how your firearm feels during operation.

Accuracy loss: While not a direct pressure sign, a significant deviation in accuracy may suggest that something is amiss with your loads—potentially related to pressure.

Understanding these signs is only part of the equation; knowing how to respond when you encounter them is essential for safe reloading practices.

Diagnosing common issues

When you notice one or more pressure signs, it's vital to diagnose the underlying issues promptly. Here are some common problems that can lead to elevated pressures and their corresponding fixes.

1. Incorrect powder charge

One of the most frequent causes of excessive pressure is an incorrect powder charge. This could be due to either an overcharge or a miscalculation during loading.

Fix: Always double-check your measurements before charging cases. Use a reliable scale and verify zero before each session. If you suspect an overcharge, pull bullets from any affected rounds and start again with proper data from reputable manuals.

2. Poor brass quality or condition

Using worn-out or damaged brass can result in unpredictable pressures. Cracked cases or those with improper resizing can lead to inadequate sealing or case head separation.

Fix: Inspect your brass thoroughly before reloading. Discard any cases that show signs of wear or damage. Consistently check for headspace and ensure proper resizing techniques are applied.

3. Primer selection

Different primers have varying sensitivity and strength levels. Using a magnum primer where a standard primer is specified can elevate pressures significantly.

Fix: Refer to your load data for primer recommendations and ensure you're using the correct type for your specific load recipe.

4. Chamber dimensions

Firearms can vary widely in terms of chamber dimensions and tolerances. A tighter chamber may not accommodate higher-pressure loads as safely as a looser one.

Fix: If you suspect your chamber may be contributing to high pressures, consult with a gunsmith to measure your chamber dimensions accurately. Consider adjusting your loads accordingly based on these findings.

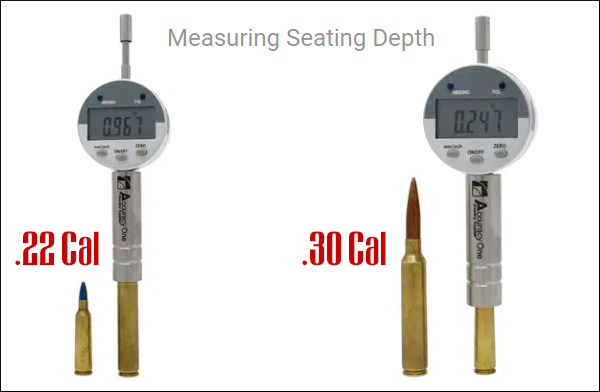

5. Bullet seating depth

Seating bullets too deeply can increase pressure significantly due to reduced internal volume within the case. This can lead to dangerous conditions if not monitored carefully.

Fix: Always follow published data for overall length (OAL) and ensure your bullets are seated within safe limits. Use a comparator to measure from the ogive (the bullet's curved front) for more precise measurements.

6. Powder selection and burn rate

Not all powders behave the same under pressure. Some powders may exhibit spiking characteristics at certain temperatures or pressures, leading to erratic results.

Fix: Stick with established load data for your chosen powder, and avoid switching between powders without thorough research into their burn rates and characteristics.

Measuring and logging pressure signs

To effectively monitor pressure signs, you'll want to keep meticulous records of your reloading sessions. Logging data helps identify trends and patterns that may indicate potential problems.

What to log

Load details: Document each component used, including powder type, charge weight, bullet type, seating depth, primer type, and brass headstamp.

Chronograph data: Record velocity readings from your chronograph to monitor consistency across different batches.

Pressure signs observed: Note any pressure signs experienced during testing—this is crucial for identifying recurring issues.

Group sizes: Keep track of accuracy metrics such as group sizes at specified distances; this helps correlate performance with pressure levels.

Environmental conditions: Factors such as temperature and humidity can affect performance; documenting these can help troubleshoot future issues.

By maintaining thorough logs, you'll be better equipped to diagnose problems as they arise and adjust your processes accordingly.

Range notes

When you take your reloaded ammunition to the range, pay close attention to how it performs:

Observe extraction; cases should drop freely from the chamber.

Look for consistent velocities across strings; large spreads may indicate underlying issues.

Monitor accuracy closely—unexpected changes might suggest problems with pressure or component integrity.

Keep an eye on your firearm; any unusual sounds or felt recoil should raise immediate concern.

Your observations during range time are invaluable for diagnosing any potential problems with your loads.

Common mistakes

Ignoring pressure signs: Some reloaders may overlook early warning signs like flattened primers or sticky extraction. Always investigate if something feels off during testing.

Fix: Develop a habit of examining every spent case after shooting and addressing any irregularities immediately.

Chasing velocity without regard for safety: The temptation to push loads for higher velocity can lead to unsafe conditions.

Fix: Prioritize safety over speed; back off at the first credible sign of excessive pressure rather than chasing numbers on a chronograph.

Inconsistent measuring techniques: Poor measuring practices can lead to unpredictable charges and inconsistencies in performance.

Fix: Use calibrated measuring tools consistently and verify scales regularly to maintain accuracy in charge weights.

Neglecting case preparation: Skipping steps like cleaning or uniformity checks can introduce variability in performance.

Fix: Take time to prepare cases properly—cleaning, inspecting, and ensuring uniformity will enhance consistency in your loads.

Not cross-referencing load data: Relying solely on memory or outdated manuals increases risk in an already complex process.

Fix: Always refer back to current load data for every session; keeping printed manuals on hand can help avoid errors from outdated information.

Conclusion

Recognizing and responding to pressure signs is essential for maintaining safety and consistency in reloading practices. By understanding what these signs mean and taking appropriate action, you can mitigate risks associated with high-pressure situations while optimizing your ammunition's performance.

As you continue refining your skills, remember that methodical work at the bench pays off far more than chasing elusive speed or accuracy goals without regard for safety protocols. Take time to log your processes diligently and review them often; this will help you develop insights into how various components interact within your specific setup.

Choose one cartridge that intrigues you and focus on creating a solid load development plan using safe practices aligned with published data. The more you practice this approach, the more familiar you'll become with interpreting results, identifying issues early, and improving consistency across your reloading efforts.