Best reloading presses for precision handloading: a detailed buyer’s guide

When it comes to precision handloading, the choice of reloading press is fundamental to achieving consistent results. This guide will delve into the various types of presses available and how they impact your reloading workflow. We’ll explore the specific features that make certain presses better suited for precision work, discussing their capabilities and limitations. The emphasis here is on practical considerations—what you should look for in a press based on your handloading needs.

Understanding reloading press types

Reloading presses come in several configurations, each designed for specific tasks. Here’s a brief overview of the primary types:

Single-stage presses

Single-stage presses are the backbone of precision handloading. They allow one cartridge to be processed at a time, which means each step can be performed with meticulous attention to detail.

Pros: Greater control over every step; ideal for load development and testing.

Cons: Slower than other types; not suitable for high-volume production.

Turret presses

Turret presses combine elements of single-stage and progressive presses. They allow you to pre-set multiple dies, making it faster to switch between operations without having to change dies frequently.

Pros: Increased efficiency over single-stage presses; still retains a fair level of precision.

Cons: Complexity may lead to errors if not properly maintained or calibrated.

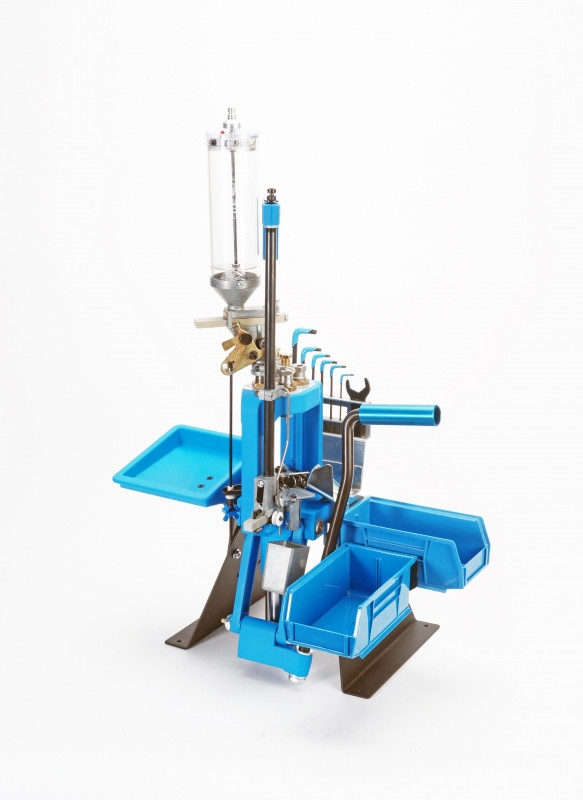

Progressive presses

Progressive presses automate much of the reloading process, allowing you to produce multiple rounds simultaneously. These are best for high-volume shooters who need to crank out ammunition quickly.

Pros: Speed; excellent for producing large quantities of ammo.

Cons: Typically less precise than single-stage presses; requires more setup and adjustment.

Understanding these types will help you narrow down your options based on how you plan to use your press.

Key features to consider

When selecting a reloading press, several features should guide your decision-making process:

Build quality

The foundation of any good press is its construction. Look for presses made from heavy-duty materials such as cast iron or steel. These materials provide stability and reduce vibrations during operation, which can affect precision.

Ram size

A larger ram size can accommodate a wider variety of dies and cartridges. This is particularly important if you plan to reload different calibers. A robust ram also helps maintain alignment during the reloading process, ensuring consistency.

Die compatibility

Not all presses are compatible with every die type. Ensure the press you choose can accommodate standard die sizes and any specialty dies you may want to use in the future.

Priming system

A reliable priming system is crucial for consistent ignition. Look for a press with an integrated priming feature that allows for smooth and accurate primer seating. Some presses offer automatic priming, while others require manual insertion.

Adjustability

Precision handloading often requires fine adjustments. Choose a press that allows easy height and alignment adjustments for dies, as well as features like micrometer adjustments for bullet seating depth.

Ease of use and setup

Reloading can be complex, so consider how easy it is to set up and operate the press. A user-friendly design will reduce frustration and improve your overall experience.

Recommended presses for precision handloading

RCBS Rock Chucker Supreme

The RCBS Rock Chucker Supreme is a classic single-stage press known for its durability and reliability. Its robust construction makes it ideal for precision handloading.

Key features:

Heavy-duty cast iron construction

4-inch ram stroke

Compatible with standard 7/8”-14 dies

Built-in primer arm with both large and small primer options

The Rock Chucker Supreme excels at providing consistent results, making it a favorite among precision reloaders. It’s particularly effective for developing loads where accuracy is paramount.

Hornady Lock-N-Load Classic

The Hornady Lock-N-Load Classic is another excellent single-stage option that emphasizes versatility and ease of use.

Key features:

Quick-change bushing system for easy die swaps

Solid steel construction

Large operating window for added convenience

Adjustable primer seater

This press stands out because of its innovative Lock-N-Load technology, allowing you to switch dies without losing your settings. This feature is particularly useful when you’re fine-tuning loads across different bullet types or weights.

Lee Precision Classic Cast Press

For those looking for a budget-friendly option without sacrificing quality, the Lee Precision Classic Cast Press is worth considering.

Key features:

Durable cast iron design

4-inch ram stroke

Features an auto-prime system

Affordable price point

While it may not have all the bells and whistles of higher-end models, the Classic Cast provides reliable performance and is well-regarded among hobbyists who prioritize value.

Dillon Precision RL 550C

Moving into turret presses, the Dillon Precision RL 550C is a standout choice for those who want speed without compromising on precision.

Key features:

Four-station design allows for quick caliber changes

Automatic indexing

Solid aluminum frame

Versatile die compatibility

The RL 550C strikes a balance between efficiency and accuracy, making it suitable for both new reloaders and seasoned veterans looking to boost productivity without sacrificing quality.

RCBS Turret Press

For a straightforward turret option, the RCBS Turret Press offers a solid build with an easy-to-use design.

Key features:

Sturdy cast iron construction

Six-station turret head

Allows for quick die changes

Priming system included

This press is appreciated for its ability to handle various cartridges while maintaining a focus on precision. It’s an excellent middle-ground solution for those who want to speed up their loading process without fully committing to a progressive setup.

Hornady Lock-N-Load Auto Progressive Press

For serious volume shooters, the Hornady Lock-N-Load Auto Progressive Press delivers impressive performance while maintaining accuracy.

Key features:

Five-station progressive design

Automatic indexing

Quick-change die bushings

Adjustable powder measure with metering system

This press is built with precision in mind, ensuring that even at high volume, each round maintains quality standards. It’s perfect for competitive shooters who need consistent ammunition.

Evaluating cost vs. value

While price is always a consideration, it’s essential to assess what you're getting for your investment. A higher upfront cost might provide long-term savings through durability and efficiency. Conversely, cheaper models may require frequent replacements or repairs, leading to higher costs over time.

When evaluating cost vs. value:

Consider your reloading volume: If you reload frequently, investing in a higher-quality press may be worth it.

Assess your needs: Think about whether you'll need additional features like automatic indexing or quick-change systems.

Look at warranties and customer support: A good warranty can provide peace of mind and indicate manufacturer confidence in their product.

Maintenance tips for longevity

To ensure your reloading press remains accurate and reliable over time, consider these maintenance tips:

Regular cleaning: Dust and debris can affect performance. Periodically clean your press with a soft brush or cloth.

Lubrication: Use appropriate lubricants on moving parts according to the manufacturer’s guidelines.

Check alignment: Regularly inspect the alignment of your dies and ram to ensure consistent performance.

Store properly: When not in use, keep your press covered or in a clean environment to avoid dust accumulation.

Common mistakes to avoid when choosing a reloading press

Selecting the right press can be daunting. Here are some common pitfalls to watch out for:

Focusing solely on price: While budget is important, don’t sacrifice quality for savings. A reliable press will last longer and produce better results.

Ignoring compatibility with dies: Ensure that the press you choose works with the dies you intend to use; compatibility issues can lead to frustration.

Underestimating your needs: Consider not just what you need now but also what you may need in the future as your reloading endeavors evolve.

Neglecting support resources: Choose brands that offer strong customer service and resources like manuals or forums where you can seek advice.

Skipping user reviews: Take time to read user experiences; they often provide insights not found in product descriptions.

Range notes

Every reloader knows that what matters most at the range is how well your ammunition performs under real conditions. Keep track of factors such as velocity spreads and group sizes when testing new loads produced on different presses.

Observe how variances in pressure signs appear when using different tools—this can be indicative of your press's effectiveness at producing consistent ammunition. Remember that accuracy at the range reflects the reliability of your bench work; thus, make sure every component in your process aligns with published data.

Checklist for selecting a reloading press

Determine your primary reloading needs (volume vs. precision).

Research compatibility with dies you plan to use.

Assess build quality and materials.

Consider ease of setup and adjustment features.

Look into warranty details and customer support options.

Read user reviews for real-world performance insights.

Visit local stores if possible to get hands-on experience with different models.

Conclusion

Choosing the best reloading press for precision handloading involves careful consideration of your specific needs and preferences. By understanding different types of presses, key features, and maintenance requirements, you’ll be better equipped to make an informed decision that enhances your reloading experience.

Invest in quality tools that align with your goals rather than chasing fleeting trends or trying to find shortcuts in the loading process. Each round you load should reflect your dedication to consistency and safety—remember that precision starts at the bench.