A beginner's setup for reloading 6.5 Creedmoor efficiently

Reloading can be an enriching experience, especially when you aim to create quality ammunition for the increasingly popular 6.5 Creedmoor cartridge. This article will guide you through a systematic approach to establishing a reloading setup tailored for 6.5 Creedmoor, focusing on efficiency and safety.

We will cover the essential tools, components, and practices needed to develop reliable and consistent loads. Remember, published data from reputable sources is your primary reference; our discussion here serves to clarify processes and enhance your understanding.

Safety first: groundwork for a safe reloading environment

Before we delve into the specifics of reloading the 6.5 Creedmoor, it’s crucial to establish a safe reloading workspace. Safety should always be your top priority.

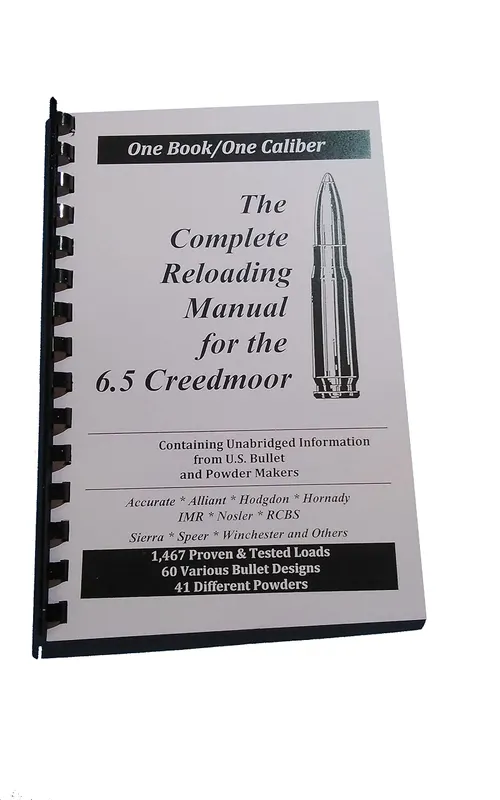

Manuals and data: Keep current reloading manuals on your bench, specifically for the 6.5 Creedmoor. These will provide essential load data, component compatibility, and safety guidelines.

Workspace: Set up a dedicated area for reloading that is clean, organized, and free of distractions. Ensure proper ventilation and avoid any open flames.

Personal protective equipment (PPE): Always wear eye protection when working with primers and powders. Consider gloves when handling chemicals or cleaning agents.

Storage: Store all powders and primers in their original containers, away from heat sources and in a secure location. Follow manufacturer recommendations for storage conditions.

Establishing this foundation will ensure you can focus on the task at hand without unnecessary distractions or hazards.

Essential tools for reloading 6.5 Creedmoor

To efficiently reload 6.5 Creedmoor ammunition, you will need several key tools and components. Here’s a breakdown of what to gather:

Press selection

Choose a press that suits your needs:

Single-stage press: Ideal for precision loading, allowing you to focus on each step individually.

Progressive press: Great for those who plan on loading in bulk, as it automates much of the process but requires more setup.

Dies

Invest in high-quality dies designed specifically for the 6.5 Creedmoor:

Full-length sizing die: Ensures that cases are resized properly for chambering.

Seating die: Adjusts bullet seating depth accurately.

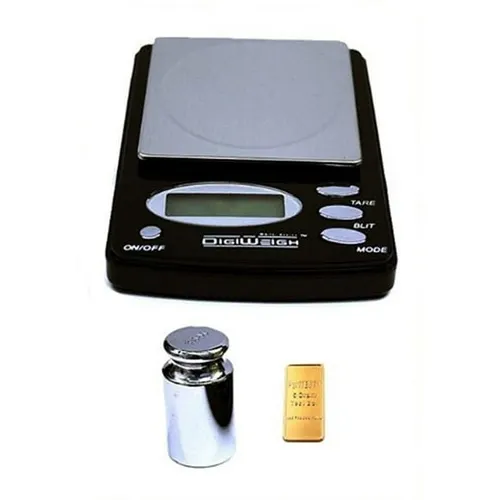

Scale and measuring tools

Precision is key in reloading:

Digital scale: For accurate powder measurements.

Calipers: To measure overall cartridge length (OAL) and case dimensions.

Case gauge: Helps confirm that loaded cartridges fit within SAAMI specifications.

Brass preparation tools

Proper brass preparation will lead to more consistent performance:

Case trimmer: Ensures uniform case length.

Case cleaner: Removes dirt and debris from cases.

Primer pocket cleaner: Ensures good primer seating.

Powder measure

A reliable powder measure allows for consistent charge weights:

- Choose one that offers ease of adjustment and reliable throw accuracy.

Other essentials

Bullet puller: Useful for correcting mistakes.

Loading blocks: Keep your cases organized during the loading process.

Labels and markers: For documenting each batch clearly.

Gathering these tools will set you up for efficient reloading sessions, ensuring consistency and safety at every step.

Component selection for 6.5 Creedmoor

Now that you have your tools ready, it’s time to select components that suit your reloading goals. The choice of brass, bullets, primers, and powder can significantly impact your results.

Brass

For 6.5 Creedmoor, consider these options:

Lapua: Known for its consistency and quality; it often provides excellent accuracy.

Hornady: A solid choice with good availability and reasonable prices.

Federal: Offers reliable performance at a competitive price point.

When selecting brass, look for uniformity in weight and dimensions to ensure consistent performance.

Bullets

The choice of bullet depends on your intended use—be it target shooting or hunting:

Match-grade bullets: Such as those from Sierra or Hornady are ideal for precision shooting.

Hunting bullets: Consider expanding options like Nosler AccuBond or Hornady ELD-X for hunting applications.

Pay attention to the bullet's weight as it affects trajectory and performance. Common weights range from 120 grains to 147 grains.

Primers

Select primers compatible with your chosen powder:

Large rifle primers: Ensure they are rated for magnum use if using certain powders to avoid ignition issues.

Brands like CCI or Federal are known for consistency in performance.

Powder selection

Choosing the right powder is critical for achieving desired velocities and accuracy:

- Popular choices for 6.5 Creedmoor include Hodgdon H4350, IMR 4350, and Alliant Reloder 16.

Refer to published data for charge weights specific to your bullet type and weight; starting low is advisable to ensure safety.

Brass preparation process

Proper brass preparation is vital for consistent performance. Follow these steps diligently:

Inspect the brass: Check for cracks or signs of excessive wear. Discard any damaged cases.

Clean the brass: Use a tumbler or ultrasonic cleaner to remove dirt and carbon residue. Clean brass not only looks good but also helps with reliable seating.

Size the cases: Use a full-length sizing die to bring cases back to specifications. Pay attention to lube application to prevent stuck cases.

Trim to length: Measure each case after sizing; trim if necessary to ensure uniformity (maximum case length for 6.5 Creedmoor is 1.920 inches).

Deburr the edges: Remove any sharp edges from trimming to prevent damage to the die or during bullet seating.

Prime the cases: Use a primer tool to seat primers firmly but not excessively deep—check for a flush fit with the case head.

By preparing brass meticulously, you ensure a solid foundation for consistent ammunition performance.

Measuring and charging powder

Accurate powder measurement is critical in preventing pressure issues while achieving desired velocities.

Zero your scale: Always start by verifying that your scale reads zero before weighing any charges.

Weigh the powder charge: Use a trickler to add powder slowly until you reach your desired weight—consult published data to find appropriate charge ranges.

Throw test charges: Before loading your rounds, throw several test charges to confirm consistency in weight.

Charge each case: Using a funnel can help prevent spills when charging cases.

Keep notes on charge weights used in each batch, including any deviations from published data—this practice fosters accountability and ease of troubleshooting later.

Seating bullets

Once cases are charged with powder, it's time to seat the bullets accurately.

Set up the seating die: Adjust the die according to your preferred overall length (OAL). Standard OAL for 6.5 Creedmoor typically falls around 2.825 inches but varies based on bullet design.

Seat a test bullet: Begin by seating one bullet and measuring its OAL using calipers—ensure you’re within safe limits according to published data.

Adjust as necessary: Fine-tune the die setting based on your measurements until you consistently achieve your desired OAL across multiple rounds.

Check seating depth regularly: As you continue loading, periodically check OALs—variations can occur due to changes in case length or die adjustments.

Accurate bullet seating plays a significant role in ensuring reliability and consistency in both pressure and accuracy.

Logging data efficiently

Documenting each step of your reloading process is essential for tracking performance and making adjustments in future sessions.

Label every batch: Include essential details such as charge weight, bullet type/weight, primer brand/type, case brand, and date loaded.

Use a notebook or spreadsheet: Maintain organized records that allow you to easily reference past loads when troubleshooting or adjusting future batches.

Record range data: After testing at the range, log velocity data (using a chronograph), group sizes, and any pressure signs observed during firing.

This practice not only enhances accountability but also aids in developing future loads with better precision.

Lapua 6.5 Creedmoor brass Deals

Prices may change. May contain affiliate links.

Range preparation and testing

Testing your newly loaded ammunition is where the rubber meets the road; it’s time to evaluate how well your efforts translate into performance downrange.

Setup for testing

Choose a suitable range: A controlled environment with sufficient distance (100 yards minimum) will yield more accurate results.

Bring necessary gear: Ensure you have a chronograph, target stand, spotting scope/binoculars, and note-taking materials at hand.

Set up targets correctly: Use appropriate targets that allow clear visibility of impact points while providing enough detail for evaluating groupings.

Conducting the test

Fire groups responsibly: Load magazines with five rounds per load variation; fire at least three groups per load while giving the barrel time to cool between groups.

Measure performance metrics:

Record velocity readings from the chronograph.

Measure group sizes using calipers or measuring tape once completed.

Note any pressure signs like flattened primers or sticky bolt lift.

Evaluating these metrics helps assess whether adjustments are necessary for future iterations of your load development process.

Interpreting results and making adjustments

After testing, it's vital to analyze collected data critically:

Evaluate SD (Standard Deviation) and ES (Extreme Spread):

- A lower SD indicates consistent velocity while lower ES shows tighter grouping potential—aim for single-digit SDs in match loads.

Compare group sizes against expectations:

- For precision shooting, seek groups under 1 MOA (minute of angle) at 100 yards; adjust loads if groups exceed this threshold.

Monitor pressure signs closely:

- If pressure signs appear earlier than expected based on published data, consider reducing your charge weight incrementally until signs disappear.

By being methodical in your evaluations and adjustments, you can fine-tune your loads effectively without compromising safety.

Common mistakes to avoid

As you embark on this journey of reloading 6.5 Creedmoor ammunition, be mindful of these common pitfalls:

Ignoring published data: Always cross-check with reputable sources; never exceed maximum charge weights without verification from trusted manuals.

- Fix: Stick with conservative approaches; always start from lower charge weights when developing new loads.

Neglecting brass prep: Skipping proper cleaning or sizing leads to inconsistent performance.

- Fix: Make brass preparation an integral part of your workflow; inspect each case thoroughly before loading.

Inconsistent measuring techniques: Relying on guesswork when measuring powder or OAL can lead to disastrous results.

- Fix: Use calibrated equipment and verify measurements frequently throughout the process.

By avoiding these mistakes through diligence and attention to detail, you'll foster a safer and more productive reloading experience.

Hornady match-grade bullets Deals

Prices may change. May contain affiliate links.

Range notes

Reloading is as much about patience as it is about technique; take time between steps to ensure everything is correct before moving forward. Consistency across all processes—from measuring powder to seating bullets—will pay dividends in performance downrange.

Remember that every round loaded should contribute toward understanding what works best within published parameters; adjust accordingly based on what you learn at the range.

Checklist for efficient reloading setup

To ensure an efficient setup process every time you head to your bench:

Verify workspace cleanliness and safety protocols.

Gather all necessary tools (press, dies, scales) before starting.

Prepare brass thoroughly (cleaning, sizing, trimming).

Measure powder accurately using tested methods.

Document each batch comprehensively for future reference.

Set up range equipment prior to testing rounds.

Following this checklist will streamline your workflow significantly while reinforcing safe practices throughout your reloading journey.

By investing time into establishing an efficient setup and adhering closely to safety protocols while utilizing published data as guidance, you’ll find yourself producing quality ammunition that performs reliably under various conditions.

Reloading is both an art and science; embrace it methodically as you craft rounds tailored specifically for the unique demands of the 6.5 Creedmoor cartridge.

Remember—this process isn’t just about creating ammunition; it's about enhancing skill sets while enjoying every moment at the bench and range alike.